Special Purpose Machine For Diesel Engine Crank

Product Details:

Product Description

Special Purpose Machine For Diesel Engine Crank

Diesel Engine Body Manufacturing Machine

Technical Features :

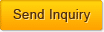

Box Stand : To mount Headstock, slides, electrical, enough top floor is kept. Approximately 30 to 35 mm top base thickness to get firm rigidity. The bottom supports are not separately joint, but integral as a one piece. Because of from bottom to top one piece, vibrations will be avoided. Necessary guarding are provided.

Headstock :Fabricated / Casted, having hardened and ground spindle. Spindle

Nose is capable to hold various collets and cutter arbor, suitable to your requirement. There are 3 head stocks 2 for Facing and 1 for Drilling(4- MSDH) operation. Each head stock having separate motors with required HP/KW.

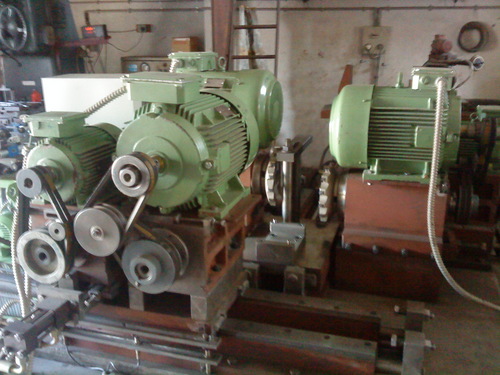

Base and Slides :Fabricated / Casted with hardened and ground rigid guide ways, keeping sliding clearances within 0.015 mm to 0.025 mm by keeper plate and taper wedges. Main slide will move (RAPID + FEED) forward by Hydraulic cylinder. Facing slides with heads will move manually by lead screw and nut. Drilling slide with 4 spindle headstock will move hydraulically.

Electrical : All electrical will be used of reputed make companies. Electrical

control panel will be mounted on box stand and operating panel box will be

mounted as suitable to machine operator.

Hydraulics : Hydraulics of reputed makes like Dowty pumps, Polyhydron valves, Yuken make solenoids are to be used.

Feed : With cutting speed 200 to 400 meters/min, depending upon the type of cutting inserts used.

Operation sequence :

(1) Mount component with locating dia.118 and dia.35 on Main Slide.

(2) The Facing operation of 4 hls. Side will be done by horizontal mounted Dia 50

2- cutters.After completion of this operation window side facing will be done by

vertical mounted Dia.250 cutter and after main slide will stop at rigid hard stop

and 4 hls. Of Dia.12 will be done by hydraulically moved 4-MSDH(Multi Spindle

Drill Head)

(3) Now the all operations are completed so unload the component and move slide to its original position and start new cycle.

Technical Parameters :

Considering the cutting speed of facing cutter 130m/min. and feed/tooth 0.1mm and cutting speed of boring 200m/min and feed o.2 mm/rev we will achieve the results are as follows :

(1) KW/HP For 250 cutter ---------------------------- 11.6/15.5

(2) RPM For 250 Cutter ---------------------------- 150

(3) Table Feed For 250 Cutter ----------------------- 225mm/min.

(4) KW/HP For Drilling operation --- 3.8/5

(5) RPM For Drilling(HSS drills 20 m/min) --- 530

(6) Table Feed Drilling --- 75 mm/min

(7) KW/HP For Dia. 50 cutter --- 3.8/5

(8) RPM For Facing ----- 1000

(9) Table Feed Boring (118/90/84, Mean 100)--- 500mm/min

Timings :

(1) Job Loading and clamping Approx. 1.5 min.

(2) Dia 84 side facing2min

(3) Dia 84 side boring10 seconds

(3) Both side Facing3 min.

(4) Both side Boring30 seconds

(5) Rapid, well etc1 min

(6) Job unloading and cleaning(cleaning by compressor) 1.5 min

Total Time For Doing All Above Operations -------- 10 minutes