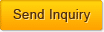

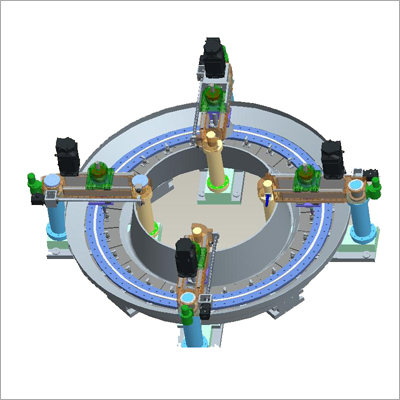

Special Purpose Machine For Wind Mill Application

Product Details:

Product Description

SPECIFICATIONS:

TABLE-1

| MAIN SPINDLE | ||

| Sr. no. | Details | Specifications |

| 01 | Spigot OD | Dia. 50 and M10 hls |

| 02 | Suitable to the U-Drills | Dia. 39 and 55 |

| 03 | Spindle RPM | 1200(max.) |

| 04 | Spindle Drive Servo Motor | 37 KW |

| 05 | Spindle Traverse | 150 mm |

| 06 | Max Torque | 11 kgf.m 107.8 N.m |

| 07 | Thrust Load | 526 kgf 5160 N |

| 08 | Y-axis travel with head stock | 460 mm |

| 09 | Y- feed ball screw servo motor | 3 KW |

| 10 | Y-axis travel feed | 1000 mm/min (max.) |

| 11 | Z-axis spindle travel feed | 0 to 1000 mm/min. |

TABLE-2

| JOB MOUNTING TABLE | ||

| Sr. no. | Parts | Specifications |

| 01 | Bottom Fixed Round Table | OD=4000mm, ID=3160mm With THK circular Rails and blocks. |

| 02 | Top Indexing Round Table | OD=4300mm, ID=3160 mm With job holding fixture mounting spigot (1) 72mm wide 15mm deep on 3864mm center. (2) 72mm wide 15mm deep on 3318 center (3) M8, ID=4200mm, No. of teeth=552 gear mounting spigot |

| 03 | Indexing table drive servo motor | 6 KW |

| 04 | Indexing table circular RPM | 0.25 |

TABLE-3

| JOBS AND OPERATIONAL SPECIFICATIONS | |||||

| Sr. no. | PCD(mm) | No. of holes | Drill size (mm) | Drill length(mm) | Component Name |

| 01 | 4040 | 80 | 45 | 60 | Base Flange-5 |

| 02 | 3825 | 80 | 45 | 60 | As above |

| 03 | 3872 | 150 | 39 | 85 | Middle Flange-3 |

| 04 | 3856 | 112 | 45 | 110 | Middle Flange-4 |

| 05 | 3876 | 128 | 39 | 60 | Middle Flange-2 |

| 06 | 3874 | 116 | 39 | 65 | Middle Flange-3 |

| 07 | 3860 | 96 | 45 | 85 | Middle Flange-4 |

| 08 | 3885 | 72 | 39 | 60 | Middle Flange-2 |

| 09 | 3724 | 132 | 39 | 80 | Middle Flange-3 |

| 10 | 3248 | 100 | 39 | 70 | Middle Flange-2 |

| 11 | 4010 | 72 | 39 | 60 | Base Flange |

TABLE-4

| GENERAL SPECIFICATIONS | ||

| Sr. no. | Details | Specifications |

| 01 | Pillar to Pillar Center Distance | 5340 mm |

| 02 | Pillar to Resting Pillar Distance | 1550 mm |

| 03 | Mail Pillar arm mounting OD | 200 mm |

| 04 | Total Height of machine | 2200 mm |

| 05 | Over all dimensions of machine | 5800 X 5800 X 2200 mm^3 |

| 06 | Total Weight of Machine | 53000 KGS. (Aprox.) |

| 07 | Coolant pressure | 40 bar |

SALIENT FEATURES OF MACHINE:

(1) Through-spindle coolant via an auxiliary pump that Supplies coolant at up to 40 bar pressure to the Cutting edge, this improves Tool Life and allows Higher speeds, This pressure throws chips from the Drilling hole and the result is high productivity and Reduce cycle time.

(2) All 4 heads will be controlled by one operating system.

(3) Also multi function Jog Handle (remote) for setting individual heads

Function.

(4) Chip Conveyer automatically moves chips along the front of enclosure,

Compresses them, drains the coolant and moves them to the discharge

Tube.

(5) Coolant Chip Sweep uses streams of coolant to continuously wash down the

Floor of the machine Enclosure. High pressure coolant through nozzles reaches all areas and washes chips and send into the chip conveyer.

(6) Whole Machine area is covered by surrounding Splash guards.

(7) 110 mm deep 4- holes in blind material at a time.

(8) Arm will swing 90degree and become solid one when it attach to the

Between pillars it becomes virtual Frame Design.

(9) Stair case at out side for looking complete machine.

(10) Oil cooler.

(11)Reputed companies like Rexroth and yuken hydraulic components to be used.

click here more details..